What is uStepper?

Introducing uStepper – Unleash the Full Potential of Your Stepper Motors!

Are you tired of the limitations of traditional stepper motors in your precision-critical applications? Do you want to ensure that your 3D printer, robot, or any other device using stepper motors delivers flawless performance every time? Look no further, because uStepper is here to revolutionize the way you use stepper motors!

uStepper takes the performance of stepper motors to a whole new level. Stepper motors are undoubtedly cost-effective and precise, making them ideal for various applications requiring precise movement. However, their one drawback is their lack of feedback, leaving you uncertain whether they have moved to the exact position you intended.

This uncertainty can lead to serious consequences, especially in critical applications like 3D printing or robotics, where precision is everything. But worry no more, because uStepper has the solution!

Imagine a stepper motor that is continuously aware of its position and its intended destination. With uStepper you can now monitor and compensate for any mishaps in real-time. Our software ensures that if anything goes wrong, uStepper will quickly and intelligently adjust its movements to get back on track, ensuring flawless results every time.

The power of uStepper lies in its integrated design. It not only drives and monitors the stepper motor with precision but also incorporates a programmable microcontroller with an extensive array of inputs and outputs. This all-in-one solution allows uStepper to intelligently monitor its position while giving you the flexibility to customize its behavior according to your specific needs.

Furthermore, we understand the importance of convenience and accessibility for professionals, hobbyists, and students alike. That’s why uStepper is fully compatible with the Arduino IDE, making programming a breeze. Whether you’re a seasoned engineer, a DIY enthusiast, or a curious student, uStepper is ready to be a perfect fit for your project.

But that’s not all! We’ve designed uStepper to be compact and easy to integrate with Nema 17 stepper motors, which means you can seamlessly install it on the back of your motors without any hassle. Say goodbye to bulky add-ons and complicated setups!

In summary, uStepper is the ultimate solution to improve the performance of your stepper motors. With its intelligent feedback system, onboard microcontroller, and Arduino compatibility, uStepper ensures unmatched precision, reliability, and ease of use.

So, why settle for uncertain movements and unreliable results with traditional stepper motors? Upgrade to uStepper today and unlock the true potential of your precision applications. Join the growing community of satisfied users and experience a whole new level of motor performance with uStepper!

Key Components

So the key ideas behind uStepper was presented in the intro. But for achieving all the nice features that uStepper provides a number of key components are required.

The key components marked on the above graphic will be discussed a bit more in detail in the following.

Microcontrol Unit (MCU)

uStepper S32 incorporates a 32-bit 84MHz Cortex®-M4 microcontroller providing more than 20 times the computation power than the previous uStepper S and S-lite controllers.

So, what do you need all that computation power for? Well, we can provide even faster reacting control loops while there’s still plenty of room for adding your custom Arduino code to do precisely what you need to do in your application !

Driver

The driver on uStepper handles the stepper motor power stage. On the uStepper S32 the same driver is used as on the uStepper S – a driver with integrated acceleration and velocity handling which offloads the MCU and gives high performance control.

One of the key issues of having a motor drive is the heat dissipation cause by switching the relatively large currents.

To accomodate this we have used large internal copper planes for distributing the heat to the whole board, thereby using the board as heat sink. This functions well up to a current of ~1-1.5 A after which a heat sink and maybe even active cooling is needed depending on the load profile. An application with continuous “high current” load will of course make a large heat build-up compared to an application with sporadic “high current” load.

Encoder

The encoder makes uStepper S32 capable of closed loop position control – eliminating one of the key issues of the open loop stepper motor control. The encoder used on uStepper S32 senses a diametrically magnetised magnet placed on the motor shaft to sense the shaft position.

uStepper S32 provides you with a resolution of 0.011 degrees !

Furthermoe, the uStepper S32 provides absolute multi-revolution feedback at a rate of up to ~200 kHz – which is used in the feedback algorithm to move the stepper motor precisely to the position you command it to!

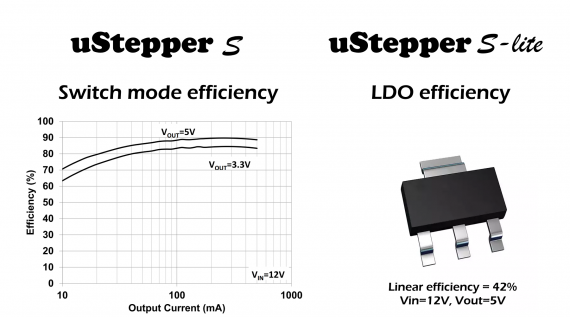

Voltage Regulator

The stepper driver needs a higher supply voltage than 5 V in order to be able to drive the stepper motor at speeds that makes sense in most real applications. This of course requires a voltage regulator for supplying the MCU and pheripherals with 5 V or 3.3 V. Without this, the board would require two voltage sources to operate!

The voltage regulator also contributes to heat generation when lowering the supply voltage to the required 5 V and 3.3 V. The voltage regulator on uStepper S line benefits from the internal copper planes when having to dissipate some of this heat – just like the stepper driver.

The uStepper S32 incorporates a switch mode regulator allowing for up to 42V board supply voltage !

If you want to look further in to the details of the uStepper and our additional products follow the link below !